Haldia is a port township situated by the river Haldi, a tributary of the river Ganges. Serving as the hinterland of the port, the town covers an area of 109 square kilometres and has some industries that form the backbone of the economy of the town. Having some promising infrastructures, Haldia can boast to have one of the best townships in the state. The smart city has some of the finest engineering colleges and there is no dearth of producing efficient professionals who could contribute to the backbone of the economy.

The Haldia unit is one of the leading producers of lead and metal ingot, vital for the battery industry and is the largest supplier of products to Exide Industries Ltd.

Pure Lead up to the purity level of 99.98% minimum.

Lead Alloys in Ingots shape weighing approx. 23 - 30 Kgs each as per customer’s specification –

Lead

Calcium Alloys

Lead Tin Alloys

Lead Antimony Alloys

Lead Silver Alloys

Implemented and maintained Quality, Environmental, Occupational Health & Safety Management System considering all the activities, products and services.

Chloride Metals Limited is proud to recycle the used Lead Acid battery and hazardous waste of Battery Industries to safeguard our mother earth.

Malur town, also a taluk headquarter situated in the Kolar district of headquarters, almost 25 km from Bangalore. The accessibility is quite convenient by roads and railways. The economy of the town depends on the clay tile and brick industry along with the vegetation where vegetables, millets, beans, tomatoes, ragi, and maize play the main role. The town is known for having factories like Honda Cycle, Mahindra aerospace, Medinova, and other factories. Chloride Metals Limited has its largest manufacturing unit at Malur.

The Malur Unit is best known for its:Pure Lead up to the purity level of 99.98% minimum

Lead Alloys in Ingots shape weighing approx. 23 - 30 Kgs each as per customer specification -

Lead Calcium Alloys

Lead Tin Alloys

Lead Antimony Alloys

Silver Master Alloy

Small components

Implemented and maintained Quality, Environmental, Occupational Health & Safety Management System considering all the activities, products, and services in line with ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018 standards.

Chloride Metals Limited is proud to recycle the used Lead Acid battery and hazardous waste of Battery Industries to safeguard our mother earth.

SUPA Parner is an industrial area is in Ahmednagar district, Maharashtra, India. This is located at 80 kms from Pune airport. SUPA MIDC is situated on the Pune – Nagar Highway enabling good connectivity by road. The new MIDC is part of SUPA-Japanese Industrial Park which houses many factories which contributes to improving the economy of this region. Chloride Metals Limited is in SUPA MIDC at an area of 15.5 acres strategically connecting all our three Exide factories located at Ahmednagar, Chinchwad and Taloja. This unit is into manufacturing of Lead, Lead alloys, cast components and plastic granules contributing to the circular economy of the nation.

Automotive batteries unit

Automotive batteries unit

Battery Charging Unit at Plant

Battery Charging Unit at Plant

Charger at plant

Charger at plant

Charger at plant

Charger at plant

Charging unit at plant

Charging unit at plant

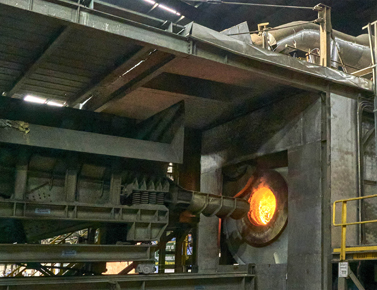

Smelting

Smelting